Australia‑Wide

Pump Refurbishment & Overhauls

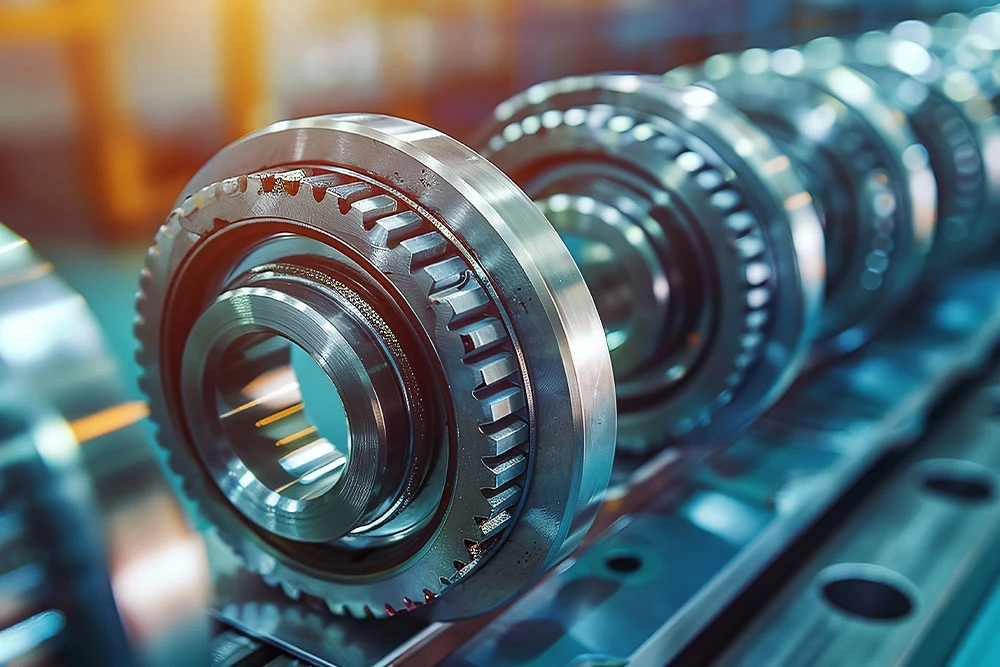

Restore performance and reliability with Plus Pumps’ end-to-end refurbishment services. We overhaul centrifugal, submersible, and process pumps across mining, water, energy, and manufacturing — from strip-and-report assessments to precision machining, ceramic linings, and ISO-grade testing.

Why Refurbish Your Pump?

Extend Equipment Life

Save up to 60% versus replacement by restoring original performance.

Improve Reliability

Reduce unplanned downtime with upgraded components and precision balancing.

Enhance Efficiency

Optimize hydraulic performance and reduce energy costs.

Upgrade Capabilities

Modernize older equipment with material and design improvements.

Full Documentation

Certified test results, photos, and QA records for every project.

Our Refurbishment Services

Strip & Condition Report

- Full disassembly, inspection, wear measurements, and photographic evidence.

- Detailed repair, upgrade, and replacement plan with a clear cost breakdown.

Mechanical Repairs & Component Restoration

- Shaft and sleeve repairs, bearing housing rebuilds, wear ring machining, and impeller re-profiling.

- Thread and stud restoration, welding, and precision machining.

Seal, Bearing & Alignment Solutions

- Mechanical seal replacement or upgrades (single, double, cartridge).

- Bearing renewal and housing remediation.

- Laser shaft alignment and pipe strain correction.

Coatings & Efficiency Upgrades

- Ceramic or epoxy linings applied to hydraulic passages to reduce wear.

- Corrosion-resistant coatings for harsh or chemical environments.

- Optional material upgrades (duplex, stainless, bronze) and impeller re‑profiling.

Dynamic Balancing & Testing

- Rotor balancing to ISO 21940 standards.

- Hydrostatic shell testing and performance verification.

- Witnessed test runs and certified acceptance curves.

On‑Site Services & Rapid Support

- Removal, installation, alignment, and commissioning assistance.

- Vibration diagnostics, baseplate remediation, and condition monitoring.

6 Key Steps

How We Bring Your Pump Back to Life

Collection or Site Removal

We pick up or disassemble on site.

Strip & Inspect

Complete teardown and wear assessment.

Quote & Plan

Options for repair, upgrade, or replacement.

Repair & Upgrade

Precision machining, coatings, and part replacements.

Test & Certify

Hydrostatic and performance tests with full documentation.

Return & Reinstall

Recommissioned on site or delivered ready to run.

Where Our Solutions Deliver

Mining & Mineral Processing

Extend equipment life and maintain continuous production with pumps rebuilt to handle abrasive slurries and harsh operating conditions.

Water & Wastewater

Ensure reliable flow and reduce downtime in critical municipal and industrial water systems.

Oil, Gas & Petrochemical

Restore safety and efficiency in demanding fluid transfer and process applications under high pressure and temperature.

Marine & Dredging

Maximize uptime for dewatering, slurry handling, and dredge operations in challenging marine environments.

Pulp & Paper

Improve process reliability and reduce energy use in fiber processing and stock handling systems.

Chemical & Process Industries

Enhance corrosion resistance and performance in aggressive chemical transfer and processing applications.

Food & Beverage

Maintain hygienic standards and consistent throughput with precision refurbishment for sanitary pump systems.

Why Choose Plus Pumps

OEM-Level Workmanship

All repairs meet or exceed original specifications.

Any Brand, Any Pump

Centrifugal, submersible, vertical turbine, PD, and legacy models.

Certified Testing

ISO 9906 performance testing, hydrostatic pressure testing, and vibration verification.

Faster Turnarounds

Emergency services and expedited repairs available.

Full Lifecycle Support

Reverse engineering, material upgrades, and efficiency improvements.

Frequently Asked Questions

What types of pumps can you refurbish?

We service all major types, including centrifugal, submersible, vertical turbine, positive displacement, and hygienic pumps — regardless of brand or age.

What does a strip & report include?

It involves complete disassembly, cleaning, wear measurements, inspection photos, and a detailed repair or upgrade proposal with cost estimates.

Can refurbishment improve pump efficiency?

Yes. Upgrades like hydraulic re-profiling, ceramic linings, and precise alignment often improve efficiency and reduce energy consumption.

Do you offer on-site services?

Absolutely. Our team can handle removal, installation, laser alignment, vibration diagnostics, and commissioning support directly on-site.

How do you ensure quality after refurbishment?

All refurbished pumps undergo hydrostatic pressure testing, mechanical run tests, and ISO 9906 performance testing, with certified results provided.

What’s the typical turnaround time?

Turnaround depends on the scope, but we offer expedited service for critical equipment to minimize downtime.

Can you refurbish obsolete or discontinued pumps?

Yes. We can reverse-engineer and manufacture replacement parts for pumps no longer supported by the OEM.

What documentation do you provide after service?

You receive a full as-built report including photos, dimensional records, balance certificates, coating QA data, and test results.

Are warranties offered on refurbishment work?

Yes. We offer workmanship and coating warranties (12–24 months) based on application and duty conditions.

How do I get started?

Simply request a strip & report or quote. We’ll assess your pump and provide the best solution to restore performance and reliability.

Get Your Pump Back to Peak Performance

Talk to our engineering team today for a free strip & report or request a rapid quote.

- info@pluspumps.au

- 08 6500 3288

- 4 Karratha Street, Welshpool, Western Australia 6106

How We Help

- Equipment sales & rentals

- Project support & site assessments

- Maintenance & spare parts